As part of the approval process for new construction or renovation the disposal of domestic effluent needs to be considered. In suburban areas where council sewerage connections are available it is generally a simple connection however in more rural areas an independent “on-site waste treatment and disposal system” needs to be designed and installed. An on-site waste system consists of a treatment tank system and a disposal field to perform final treatment and dispose of the liquid component of the effluent.

The design of the system needs to meet the local, regional and national codes for on-site waste system design and management requirements. The size of treatment system required is based upon the number of bedrooms or potential bedrooms in the dwelling. A potential bedroom could be an office or den that could conceivably be used as a bedroom at some point in the future.

The size of the disposal field for the on-site waste system is based on the quality of the soil in the disposal field area to recieve, hold, treat and dispose of the liquid portion of the effluent.

An on-site waste system (or OSW system) needs to accept both “black” water from toilets as well as “grey” water from showers, sinks, dishwashers etc. This effluent needs to be treated to prevent the bacteria, solids and disease causing organisms from contaminating the environment and watershed. The solids component of the effluent is generally held and treated in the septic tank while the treated (but still contaminated) liquid flows to a disposal field (and effluent is approximately 98% liquid).

All treatment systems contain treatment tanks and disposal areas. Treatment of the effluent takes place within the tank system as well as within the soil matrix of the disposal area. Primary treatment systems depend upon the soil for treatment to the largest extent, Secondary systems provide more treatment within the tank system and less treatment within the soil and Tertiary treatment systems provide the most treatment within the tank system.

Where the lot size is large without nearby sensitive recieiving environments like ponds, rivers or beaches a primary system can generally be used. As the quality of the soil drops or the sensitivity of the recieving environment increases a higher level of treatment i.e. Secondary or Tertiary treatment will be required. This is why a site visit and analysis of the soil and surrounding environments is an important part of the design process. New Zealand on-site waste design code is very specific and as design engineers, Ashby Consultants are here to help you select the system most suited for your site and project.

A brief description of the On-site options

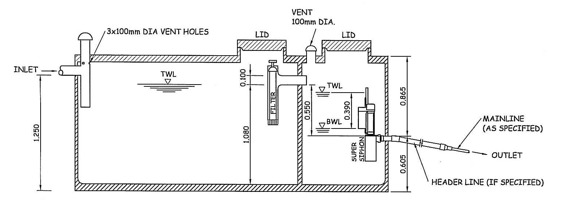

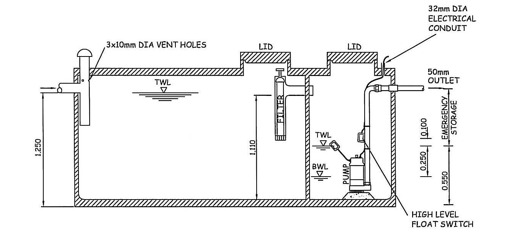

Modern Primary Treatment with a standard filtered septic tank and drainage trenches

This is generally the simplest and least expensive system typically consisting of a single concrete septic tank with two chambers (see the diagrams below). The primary chamber receives the effluent and a biological filter between the primary and secondary chamber retains the solids in the primary chamber while allowing the liquid to flow to the secondary chamber. From the secondary chamber either a pump or gravity siphon doses the liquid to a disposal field. The disposal field typically consists of 200mm x 200mm trenches filled with metal, perforated pipe and 25mm squirt lines.

These trenches are typically overtopped with grass, need to be laid absolutely level (along the contour on sloping ground) and need to be fenced to prevent stock access. The dosing of septic fields is an important change over older trickling fed septic fields which had a bad habit of “creeping failure”.

The intermittent doses with resting periods in between allow the effluent to be lightly and evenly distributed over the entire field and then the field “rested” to allow the effluent to be treated by the natural bacteria in the soil and for the water content to soak into the surrounding soil, evaporate into the surrounding air, and be taken up by plants specifically planted within the field. Primary systems require larger lots, good quality topsoil and are more suitable for rural installations.

For primary systems the two types of dosing from the tank to the field are:

Gravity Siphon Dosing

If the site is sloping and allows the level of the disposal field to be 3 metres or more below the top of the septic tank then a gravity dosing siphon can be used. A siphon allows for intermittent discharge (dosing) without using any power, pumps or moving parts. This type of system is reliable, inexpensive and requires very little maintenance.

For more on how a dosing siphon works see the Vortech Super Siphon website.

Pump Dosing

If the site for the disposal field is at approximately the same level as the septic tank or above the septic tank then a pump is needed to distribute the effluent to the disposal field. The pump requires a source of electricity and is controlled by a float switch in the secondary chamber. Because the pump or switch can fail a high water alarm needs to be installed with a visual and auditory alarm panel placed in a location that the home owner will be alerted by it.

Advantages of Primary Treatment systems

- Generally simpler and more reliable

- Generally less expensive

- Siphon dosed systems need no power

- Very little maintenance most of which can be done by homeowner if they so choose

- Low cost installation and maintenance

Disadvantages of Primary Treatment systems

- Needs a larger lot

- They can have a bit more odor

- Requires relatively good soil and topsoil for soakage in the disposal field.

Secondary Treatment

Secondary treatment processes the effluent to a better quality within the tank system prior to sending it to a disposal field. Because the quality of the effluent coming out of the system is higher there is less potential for odor and the effluent can be distributed by dripperlines pinned to the surface of the ground so no trenches or metal required.

Dripperlines are approximately 20mm diameter plastic lines with a small controlled dripperhole usually at half metre increments that allow for controlled dripping of the effluent. Dripperline disposal fields can be run up and down hills around and through existing bush, orchards or landscaping with even distribution of the treated effluent along the entire run. They can be mole plowed into a lawn or landscaped area so they are not visible. Like the trenches discussed above, the area dripperlines are placed in does need to be fenced from stock to prevent damage to the lines.

Secondary treatment is the best choice for smaller lots, environmentally sensitive locations or lots that don’t lend themselves to a level trench type disposal field with good topsoil described for primary systems above.

Advantages of Secondary Treatment systems

- Better treatment of effluent within the unit

- Generally less odour

Advantages of Dripperline Disposal

- No large trenches

- No requirement for level disposal field

- Can be easily run within and under established plantings or lawn

- Better suited for small or sensitive lots- systems can be sited closer to sensitive environments like beaches, ponds, watercourses etc.

Disadvantages of Secondary Treatment systems

- Purchase cost is more than for primary treatment

- All secondary treatment systems require electrical power (ongoing running costs)

- More complicated than primary treatment- more pumps, alarms etc.

- Requires regular maintenance/inspections by technician, $

150+ per inspection

- Some systems (aerated) make a continuous noise

- Typically more expensive than a primary system to install and maintain.

There are different methods of secondary treatment, the two most popular of which are discussed below:

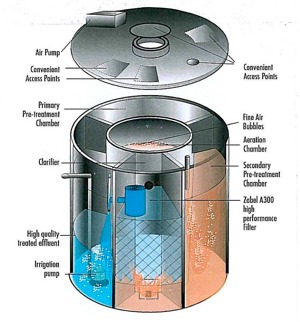

Secondary Aerated Treatment using an Aerated Blower

This system treats the effluent within the unit by filtering, then blowing/bubbling oxygen (air) through the effluent to enhance the microbial growth and treatment of the effluent prior to discharge.

The advantages of aerated treatment are as follows:

-

Can sometimes be less expensive to purchase than other forms of secondary treatment

.

The disadvantages of aerated treatment are as follows

- Running Costs-The blower unit is an electrically driven motor and most units run 24 hours a day, 7 days a week. Independent testing trials by the Rotorura District Council found that the aerated systems use 2 to 5 times the power of a packed bed secondary treatment unit. Electricity costs of systems in the trials varied from about $150 to $600 annually.

- Noise- The blower makes a continuous hum that some people find annoying. If you are considering a aerated system ask the distributor to take you to an installed and operating system for you to listen to. We reccomend the system should not be installed near decks or bedrooms where you spend significant amounts of time.

- Limited capacity for intermittent use- When the unit is first commissioned it takes time to build up a microbial colony to digest and treat the effluent. If the system isn’t constantly fed (i.e. in a holiday home situation) the system will continue to treat the effluent until it runs out of “food” and the microbial colony dies off. When the house is re-inhabited the system takes about two weeks to get back up to full microbial treatment. During that re-start time there will be less than full treatment and more exterior odours than typical for a fully functioning unit. These systems are not recommended for baches or holiday homes.

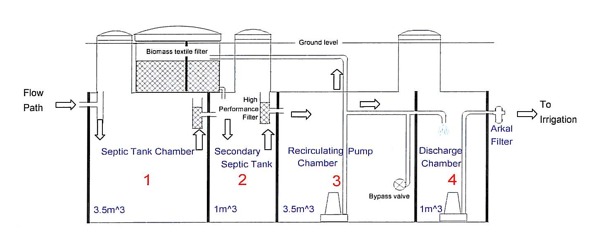

Secondary Treatment using a Textile Packed Bed Reactor (PBR)

This system more completely treats the effluent within the unit by spraying the effluent over highly porous sponge-like sheets which and allows air to circulate through it (without the need for a blower). This promotes microbial growth throughout the “sponge” that treats the effluent.

The advantages of PBR treatment are as follows

- Running costs- While it costs more to run than a primary treatment system, the circulation pumps run only intermittently (roughly 60 seconds every 15 minutes) to dose the beds. Power costs ranged from $45 - 200 annually.

- Noise- The pumps will make a small humming sound when running but the pumps are at the bottom of buried chambers and run for only 2-4 minutes an hour.

- A greater capacity for intermittent use- these systems have a “sleep mode” re-circulating capability to draw off small amounts of effluent from the main septic tank and spray down the beds even when no one is using the system for long periods of time. This keeps the microbial population alive and fully functioning with only the small recirculating pump running intermittently about 10 minutes total in 24 hours. This works well in holiday home or intermittent usage applications

.

The disadvantages are as follows

- Larger textile systems tend to be slightly more expensive to purchase than aerated systems.

Why use Ashby Consulting Engineering?

As design engineers at Ashby Consultants we don’t have affiliations with any particular manufacturer or installing drainlayer so can make an unbiased recommendation. We understand that it is an expensive purchase and work with you to make sure you get the system that is right for you and your site. Every site is different but in general we prefer to keep the system as simple (and inexpensive) as possible.

Where the sites allow it we generally recommend either siphon or pump dosed primary systems as they are reliable and require little on-going maintenance. If a particular site calls for a secondary system we generally recommend the secondary textile PBR systems based on their lower power use, quieter operation and intermittent loading capability.

There are many different manufacturers of these systems and we try to recommend ones by manufacturers that have been in business for a long time and that have a good record service and support. We also prefer systems that have been independently tested as part of the Environment Bay of Plenty testing scheme (Access the testing program website and results here).

Should you have questions or would like to discuss your particular requirements, don’t hesitate to contact Ashby Consultants.